What is the PumpBuddy?

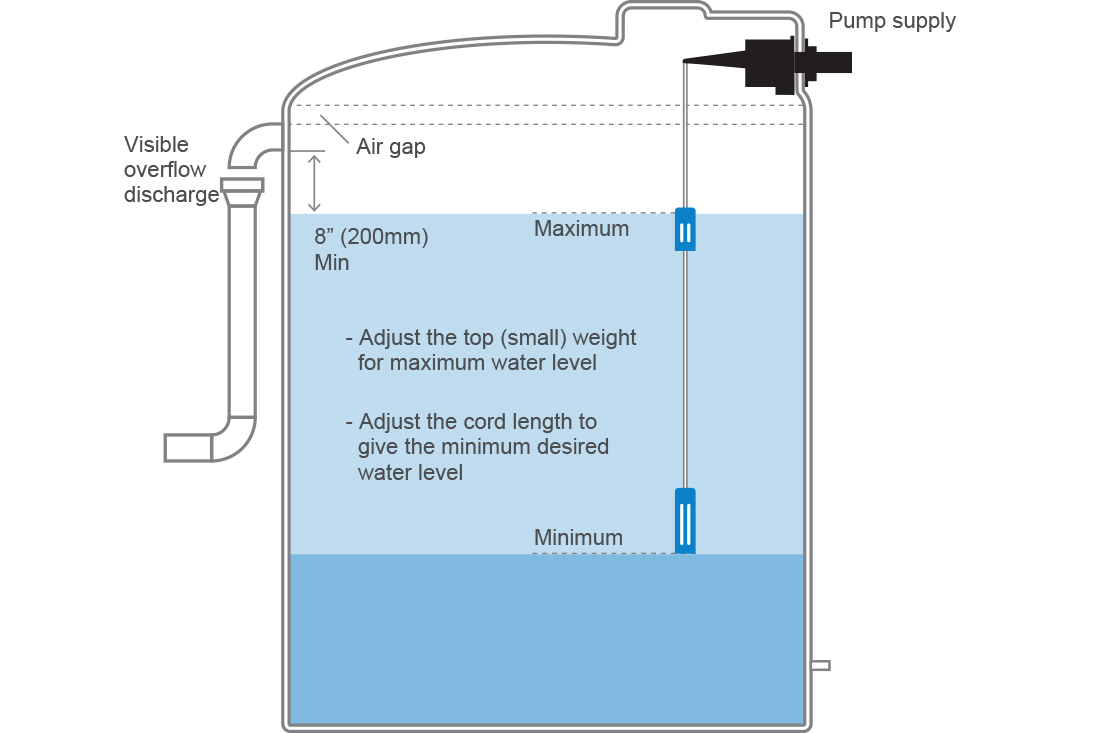

The Pump Buddy valve is an inlet control device, which allows for variable minimum and maximum water level settings with a water tank. The traditional ball cock valve such as an AP/72 continuously restricts the flow until it becomes a trickle, therefore extending the pump run time required to close the valve.

By optimising the water filling process the PumpBuddy Valve significantly decreases pump run time. This reduction leads to lower power consumption, which is essential for farmers looking to manage their operating costs.

The valve’s design not only minimises energy use but also prolongs the pump’s lifespan. The PumpBuddy Valve is either fully open and flowing, or fully closed. This ultimately decreases wear and tear on the pump and giving it an extended life.

“Pumps prefer to run once, fill most of that tank and close off. Wear and tear is increased when they turn on and off repeatedly,” says Mark.

Impressive results in the lab and on-farm

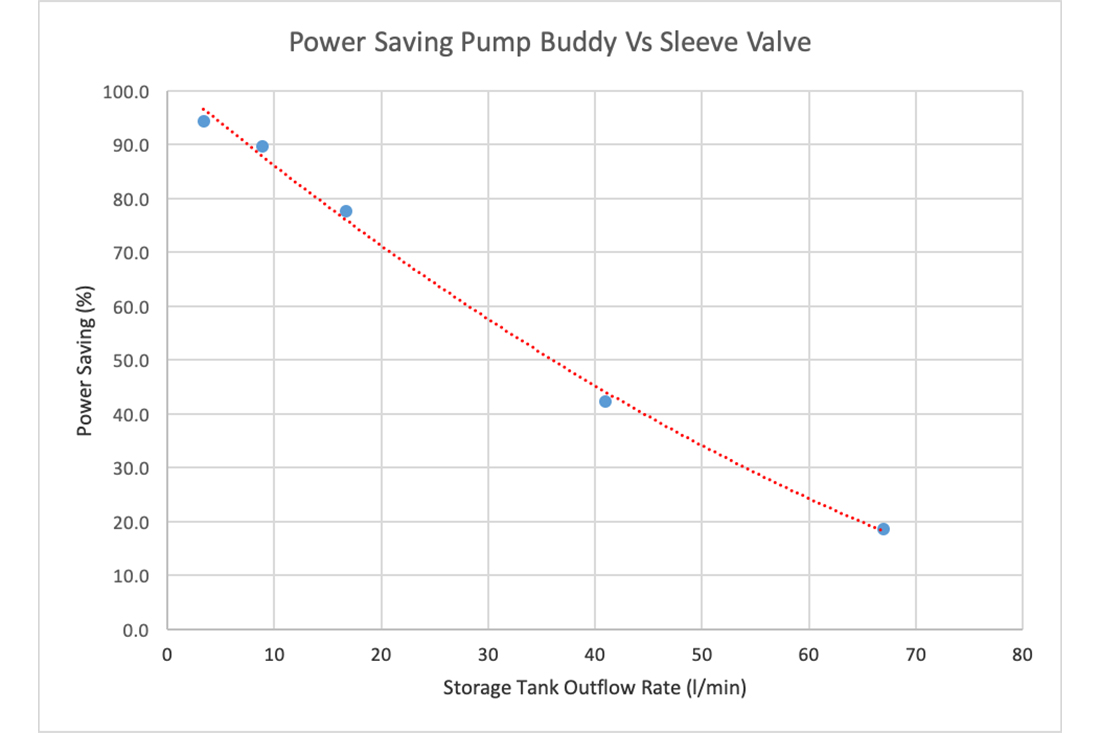

Apex WetLab has released research comparing Full Flow Differential Valve with Sleeve Type Ball Cock Valves. It conducted tests at various flow rates from 3 to 67 litres per minute, demonstrating remarkable results.

In a continuous loop setup between a supply tank and a trough, the data showed power savings of up to 90%. Interestingly, lower outflow showed the best savings, which mimic standard farm use and typical trough filling.

Farmers who have adopted the PumpBuddy Valve report notable reductions in their energy bills on-farm, making it an attractive investment in today’s high energy cost environment.

With the ability to optimise how their pumps are operating, farmers can maintain water tank levels while managing energy costs effectively.